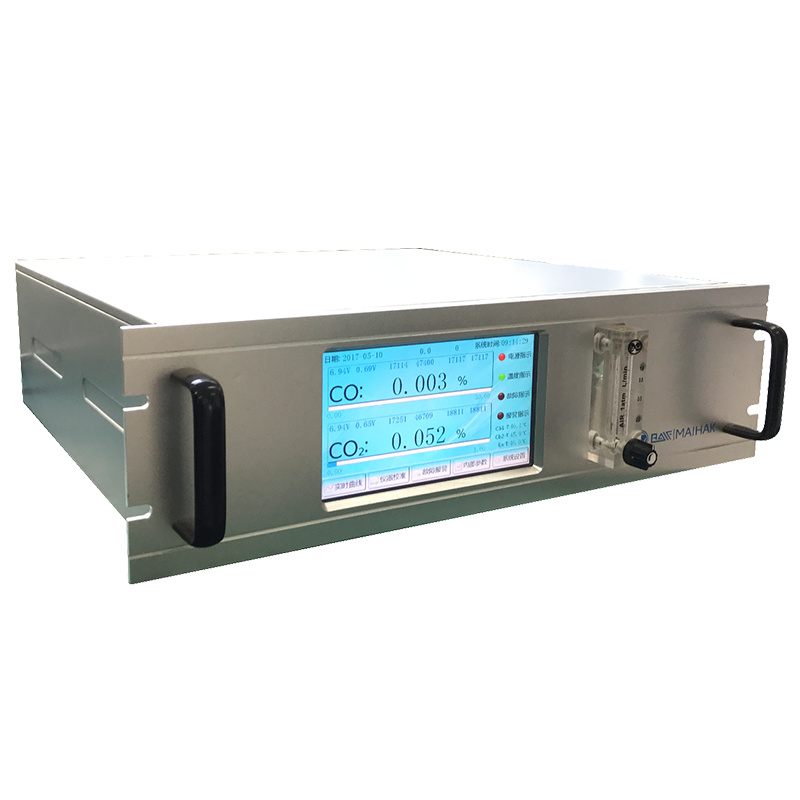

QGS-08CN modular gas analyzer

Measurement principle

QGS-08CN modular gas analyzer is based on infrared photoacoustic method to realize multi-componen detection. A variety of measurement modules can be optional to meet the requirements of measuring multiple gas concentrations. Available modules include infrared photoacoustic module, paramagnetic detection module, electrochemical detection module, thermal conductivity detection module or trace water detection module. Up to two thin-film microsound detection modules and a thermal conductivity or electrochemical (paramagnetic oxygen) module can be assembled simultaneously. According to the range, measurement accuracy, stability and other technical indicators, the analysis module is selected.

Technical parameter

Measuring component:CO、CO2、CH4、H2、O2 Etc.

Range:(0~100)% (Different specifications can be selected within this range)

Minimum range: CO :(0~50)x10-6

CO2:(0~20)x10-6

CH4:(0~300)x10-6

H2:(0~2)%

O2:(0~1)%

N2O :(0~50)x10-6

Zero drift :±1%FS/7d

Range drift :±1%FS/7d

Linear error :±1%FS

Repeatability :≤0.5%

Response time:≤20s

Power :﹤150W

Power supply:AC(220±22)V 50Hz

Weight :about 50Kg

Instrument characteristics

●Multiple analysis modules: A QGS-08CN analyzer can be loaded with up to 3 analysis modules. An analysis module includes the basic analysis unit and the necessary electrical components. Analysis modules with different measurement principles have different performance.

●Multi-component measurement: QGS-08CN analyzer with with a time interval of 0.5…20 seconds (depending on the number of components measured and the basic measurement range) measures all components simultaneously.

●Touch screen: 7 inch touch screencan display real-time measurement curve, easy to operate, friendly interface.

●Concentration compensation: can compensate the cross interference to each component.

●Status output: QGS-08CN has a total of 8 relay outputs, including zero calibration state, terminal calibration state, fault state, alarm state, etc. Users can choose the corresponding output position for a certain state output according to the actual situation.

●Data retention: When you perform calibration or other operations on the instrument, the instrument can maintain the data status of the current measurement value.

●Signal output: standard current loop output, digital communication.

(1) There are 4 analog measurement outputs (4... 20mA). You can select a measurement component corresponding to a signal output, or you can select a measurement value output corresponding to multiple output channels.

(2) RS232, MODBUS-RTU that can be directly connected to the computer or DCS system.

●Intermediate range function: that is non-zero starting point measurement.

●Zero gas: For zero calibration, two different zero gas values can be set as nominal values. This allows you to calibrate different analysis modules that require different zero gases. You can also set negative values as nominal values to compensate for lateral sensitivity interference.

●Standard gas: For terminal calibration, you can set 4 different standard gas nominal values. You can also set which measurement components are calibrated with which standard gases.

Product application

●Environmental monitoring such as emissions of air pollution sources;

●Petroleum, chemical and other industrial control;

●Agriculture, health care and scientific research;

●Determination of gas content in various combustion tests in laboratory;

●Air quality monitoring in public places;